In this Article

To create and distribute documentation fully automatically: this is the dream of many companies that have to create a wide variety of different documentation – from spare parts catalogs to operating manuals and product information. But the reality is often different: documentation must be created manually and very laboriously from different systems. Although there are automation possibilities, these automations are usually only worthwhile for large and time-consuming or for very many small documentations. For this SEAL Systems offers solutions for years, which are well accepted in the industry.

But how can we also support those who want to produce documentation in small quantities or in individual compilations? For this SEAL Systems has decided to simplify the manual creation of documentation. This enables more users to automate their processes at least partially and thus save time. In our new blog series “Documentation creation with SEAL Systems” we present how this works exactly.

In our first blog post of the series, we will show you how you can create documentation from SAP in four simple steps using ready-made templates.

Step 1: Which Files Should Be Used?

Documentation creation begins with determining which files to use. To find these files, you have two options in this case, which you can also combine in any way you like:

- Find all files by SEAL Systems structure resolution (that means our solution finds all documents which belong to a business object)

- Customer specific coding to determine the files with subsequent transfer to the SEAL Systems solution

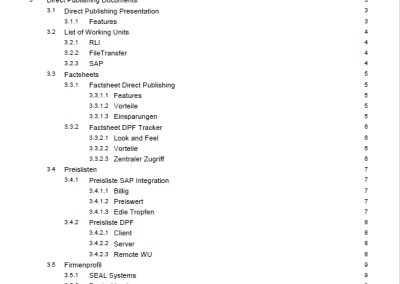

The result of this file query is initially a flat list of documents without any structure information.

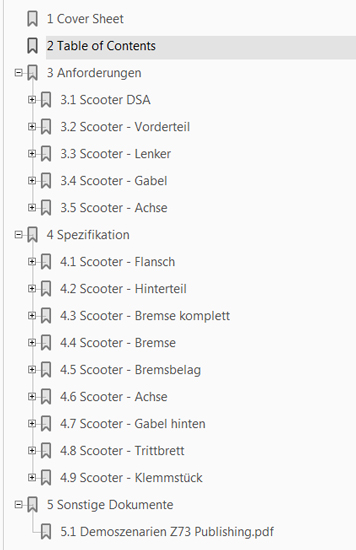

Step 2: How Do the Files Get Into a Structure?

There are two ways to create the structure for your documentation: You can define the structure using ready-made templates or you can create the chapter structure manually. How this manual creation of arbitrary structures works, we will explain shortly in detail in the second part of our blog series “Documentation Creation with SEAL Systems.

When using a template, the chapter structure is transferred to the current job. You can also include placeholders in the templates. During creation, the system then checks whether a file corresponds to a placeholder. If this is the case, it is transferred to the chapter structure in the place of the placeholder.

Step 3: How Do I Determine the Layout of the Documentation?

The files are now structured, now it must be determined which layout should be used. A large number of templates are already available in the standard system. However, customer-specific layouts can of course be added. If desired, it is also possible to assign specific layouts at file level in addition to the global settings for the entire document. This gives you maximum flexibility when creating your layouts.

Here is an example of the layout information transferred from SAP to the DPF (Digital Process Factory®):

Step 4: How Should the Documentation Be Stored and Processed?

Finally, it has to be determined where the document will be stored (e.g. as a new DIS) or who will receive the document by e-mail. This is also realized via the parameters of the order.

With the solution from SEAL Systems you get your documentation from existing SAP documents in only a few steps – double data storage or additional applications like editorial systems are not necessary.

Contact us

Fill out the form below to receive more information or let us know what we can do for you.